Our facility is equipped with the most advanced technologies in the industry delivering leading-edge precision, volumes and efficiencies. We are fully staffed seven days per week with robotic and lights-out capabilities. Wrobel is your answer for projects of any complexity or size.

Consulting and Design for Metal Manufacturing

We have a fully integrated Engineering Department equipped with cutting-edge technologies and staffed by a team of professionals — each having a minimum of 20 years experience. Our engineers can identify opportunities for design improvements, building higher quality and manufacturing efficiencies into every project.

- CAD

- 3D Models

- 3D Printing

- Off-Line Programming

- Reverse Engineering

- Dimension BST 3D printing system

Our facility is equipped with the most advanced technologies in the industry delivering leading-edge precision, volumes and efficiencies. We are fully staffed seven days per week with robotic and lights-out capabilities. Wrobel is your answer for projects of any complexity or size.

- Amada M-2545 8ft x 3/16

- Amada LCG 3015 - 5ft x 10ft capacity

- Bystronic 3015 With auto loader - 5ft x 10ft capacity

- 1, Amada EM-2510 electro mechanical with auto loader

- 1, Amada EM-2510 electro mechanical

- 1, Amada King II with auto-loader

- 1, Pega-S with auto-loader

- 1, Amada RG 50 ton press brake 6’

- 1, Amada RG 80 ton press brake 6’

- 1, Amada RG 80 ton press brake 8’

- 1, Amada Promecam HFB press bake 50 ton 6’

- 1, Amada FAB press brake 100 ton 10’

- 1, Amada HDS press brake 140 ton 10’

- 3, Amada FAB III press brake 80 ton 6’

- Amada Astro II 100nt HDS 1030 fully robotic press brake

Our laser cutting systems utilize the latest advances in laser manufacturing technology for high cutting speeds and the flexibility to process a wide range of materials.

- Stainless Steel

- Aluminum

- Cold Rolled Steel

- Hot Rolled Steel up to 1/2 inch thickness

- Amada LCG 3015 - 5ft x 10ft capacity

- Bystronic 3015 With auto loader - 5ft x 10ft capacity

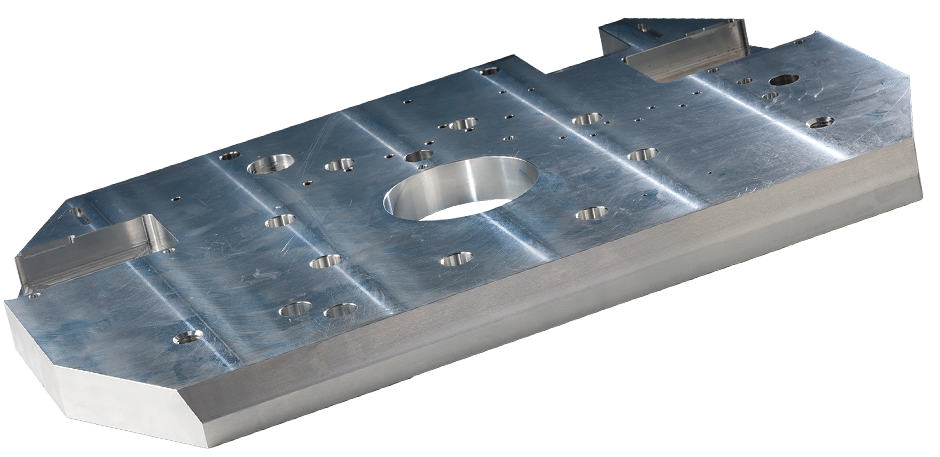

Wrobel delivers precision CNC machining services at close tolerances for a wide range of materials including aluminum, steel, stainless steel, brass, copper, and most plastics. Our Milling equipment is controlled by customer supplied CAD models or by files engineered in-house from supplied drawings. We offer CNC machining services in the USA with the capacity to handle the largest and most complex orders with ease.

- Aluminum

- Steel

- Stainless Steel

- Brass

- Copper

- Most Plastics

- 1, Fanuc Robo Drill Mate

- 1, Fanuc Robo Drill XT14A w/pallet changer

- 3, Bridgeports

- 3, Hurco VMX 50

- 2, Hurco VMX 42

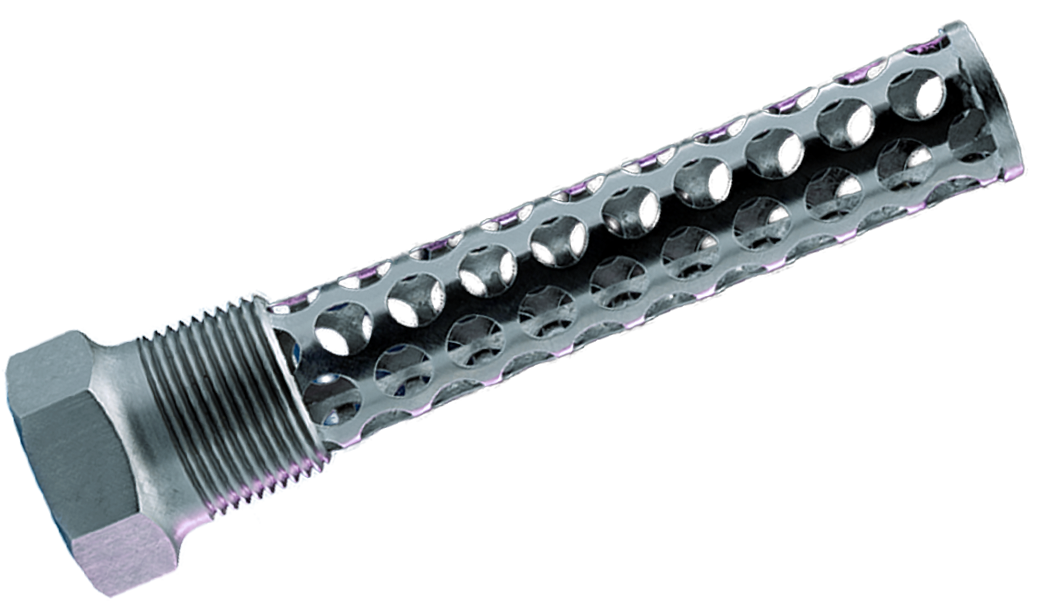

Wrobel Engineering offers precision turning, our equipment is capable of high-performance, dual-spindle and Y-Axis Turning providing economical production of complex parts in a variety of materials.

- Aluminum

- Brass

- Stainless Steel

- Copper

- Alloy Steel

- Most Plastics

- 1 Hwacheon Hi-Tech 250A Mill turn Lathe

- 1, Hass HL-1 Lathe with bar feeder

Wrobel Engineering offers certified welding from the finest craftsmen in the area. Utilizing state of the art equipment, our craftsmen build complex weldments for medical, military, aerospace, and commercial applications.

Certified welders on staff.

- Flux-cored arc welding (FCAW)

- Gas metal arc welding (GMAW)

- Gas tungsten arc welding (GTAW)

- Metal inert gas (MIG) welding

- Tungsten inert gas (TIG) welding

- Sciaky 75 KVA @ 50% duty cycle

- Alphil 150 KVA

- Tecna 90 – 245 KVA DC inverter resistance welder

- 2, Miller Millermatic 250 amp

- 2, Thermal Arc 300 amp

- 1, Thermal Arc 300 GTSW

- 1, Thermal Arc 300 AC/DC arc master

- 3, SanRex 300 Amp Rectifiers

We offer a wide range of finishing and polishing services to meet any customer need.

- Deburring

- Grinding

- #4 Through #8 Mirror

- Grain Finishes

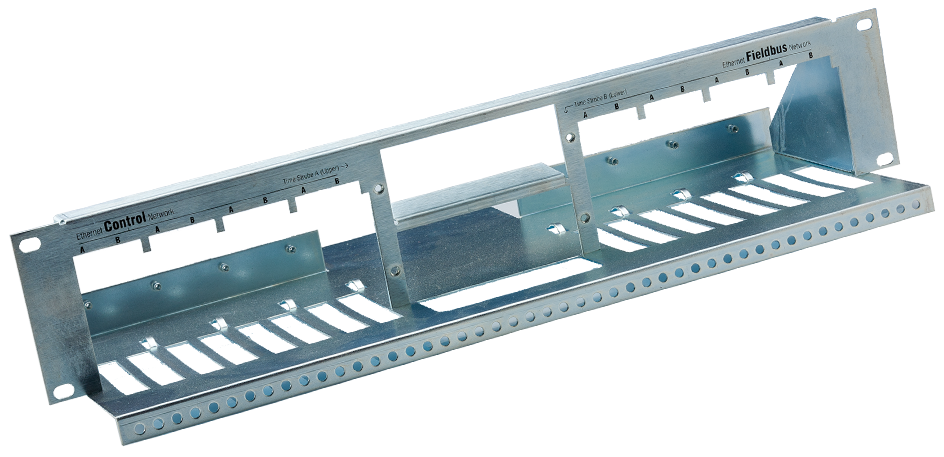

We maintain 5,000 square feet of space dedicated to EM ESD assembly providing our customers with a resource to increase efficiencies and reduce costs.

To meet the demands of the high technology industries, we have created a special Electrostatic Discharge (ESD) room. Parts such as printed circuit boards with electro-sensitive materials and other high tech equipment are handled and assembled in an electrostatic-free environment.